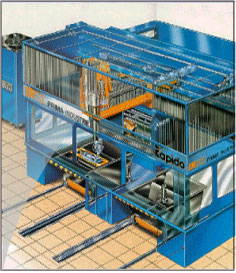

Our 2D and 3D laser cutting systems can cut seemingly impossible hole and profiling configurations that conventional punches and dies cannot, while offering +/- 0.0002″ repeatability. This saves time and the cost of producing special contour tooling and allows engineering changes to be easily incorporated. The non-contact nature of this process eliminates material distortion which in turn reduces scrap costs.

Our 2D and 3D laser cutting systems can cut seemingly impossible hole and profiling configurations that conventional punches and dies cannot, while offering +/- 0.0002″ repeatability. This saves time and the cost of producing special contour tooling and allows engineering changes to be easily incorporated. The non-contact nature of this process eliminates material distortion which in turn reduces scrap costs.

The laser cuts carbon steel, stainless steel and aluminum, titanium, copper, brass, bronze, and almost any alloy; by directing the output of a high power laser – by computer – at the material to be cut. The material then either melts, burns, or vaporizes, leaving an edge with a superior quality surface finish that’s free of burrs.

When used in conjunction with our metal stamping and deep draw services, we’re able to achieve a high degree of precision, design flexibility and significant tooling cost savings.

We cut materials with thicknesses up to:

- 1 inch carbon steel

- 1 inch stainless steel

- 3/4 inch aluminum

Work area is 31 inches (Z) x 69 inches x 135 inches

Why not call us today to learn more about our laser cutting services? Let’s talk about how we could save you money on your metal stamping or deep draw stamping projects.

Contact Us Now